Product Design & Development

Home / Our Services / Engineering / Product Design & Development

Turning Vision into Reality

In modern competitive markets, a great idea isn’t enough — your product must deliver on performance, manufacturability, cost, and reliability. At JENA TOOL, we bring your ideas to life using intelligent engineering, precision machining, and validation-driven processes. Our focus is to help you achieve faster development, smarter designs, and superior product reliability — keeping you ahead of the competition.

Why Great Design Matters

A brilliant product design gives you a head start — but without a robust process behind it, even the best idea can fail.

Our team blends innovation, engineering expertise, and real-world production insights to ensure your design is strong, scalable, and ready for manufacturing.

With our structured workflow, we help you eliminate problems early, reduce revisions, and ensure smooth production from concept to launch.

What We Offer

- Production Process Engineering:

We define and engineer every stage of production: material flow, machine operations, quality checkpoints, workforce interaction.

Our goal: maximize throughput with minimal waste, ensure consistency part-to-part, batch-to-batch.

- Yield & Quality Assurance: Processes designed to reduce defects, improve accuracy, and stabilize long-term output.

- Safety, Ergonomics & Compliance: Every process follows strict industry standards for safe and efficient operations.

- Reliability & Repeatability: Our engineered processes ensure each batch meets required specifications—every single time.

- Efficiency & Cost Optimization : Lean manufacturing principles that minimize waste and maximize productivity.

How We Work

- Assessment & Planning: Understanding requirements, materials, tolerances, and end-use applications to build a strong foundation.

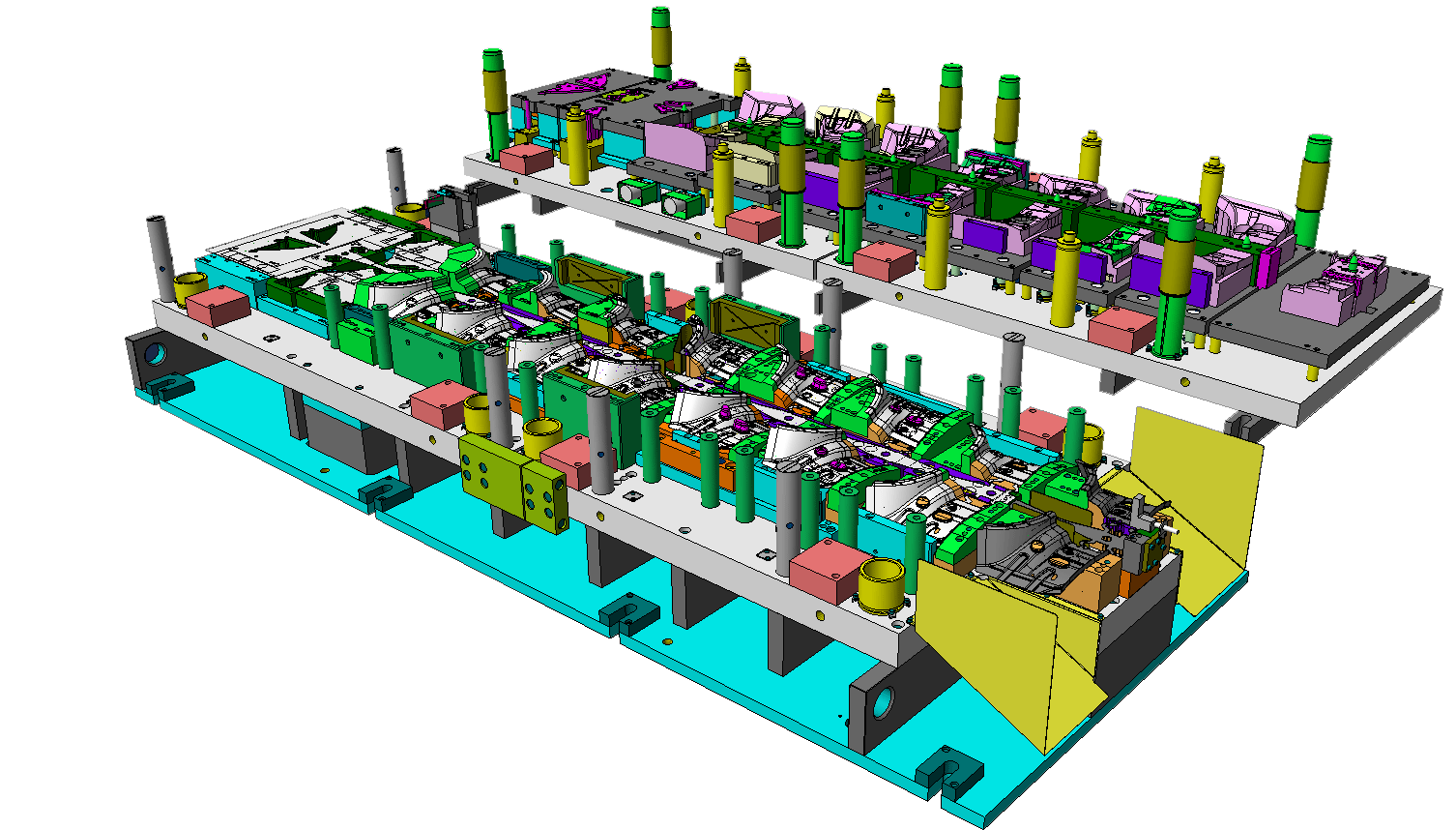

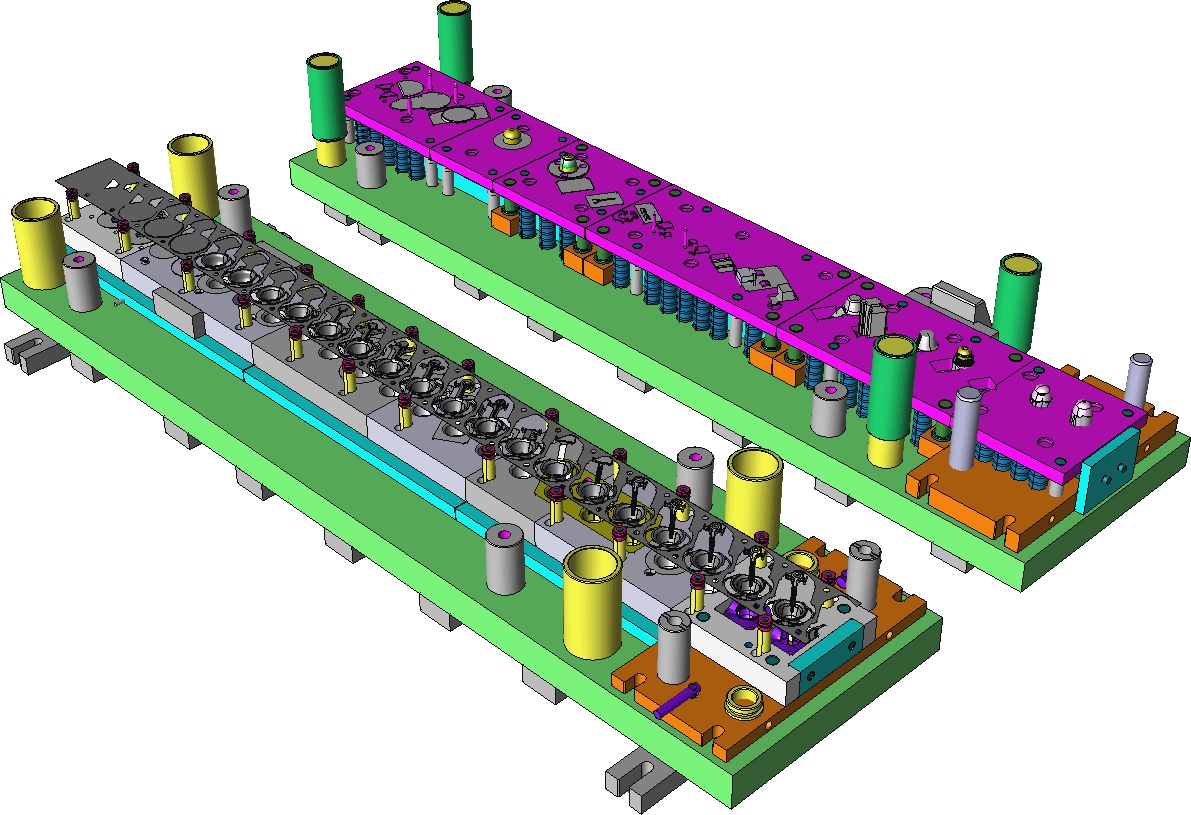

- Process Design & Simulation: Developing machining plans, toolpaths, fixture designs, and production flows using modern engineering tools.

- Prototyping & Pilot Runs: Testing small batches to validate accuracy, performance, and manufacturability.

- Implementation & Scaling: Setting up the final process for full-scale production with reliable repeatability.

- Monitoring, Improvement & Support : Continuous evaluation, adjustment, and technical support for long-term efficiency.

Ready to Start Your Project?

Our engineering team is here to help you design, develop, and scale your next product with accuracy and confidence.

FAQ

- Jena Tool provides precision machining, product design support, process engineering, prototyping, and full-scale manufacturing solutions for various industries.

- Yes. We handle one-off prototypes, small batches, and high-volume production with consistent quality.

- Absolutely. Our engineering team helps improve manufacturability, reduce cost, and enhance performance through design refinement.

- We work with automotive, aerospace, medical, industrial machinery, robotics, and custom engineering projects.

We work with a wide range of materials including aluminum, steel, stainless steel, brass, copper, titanium, and engineering plastics.

Your Benefits

Lower Risk — fewer defects, fewer surprises, and safer operations.

Faster Time to Market — optimized processes accelerate delivery and reduce lead times.

Cost Savings — better process flow lowers production costs per part.

Scalability — processes designed to expand with your production needs without compromising quality.