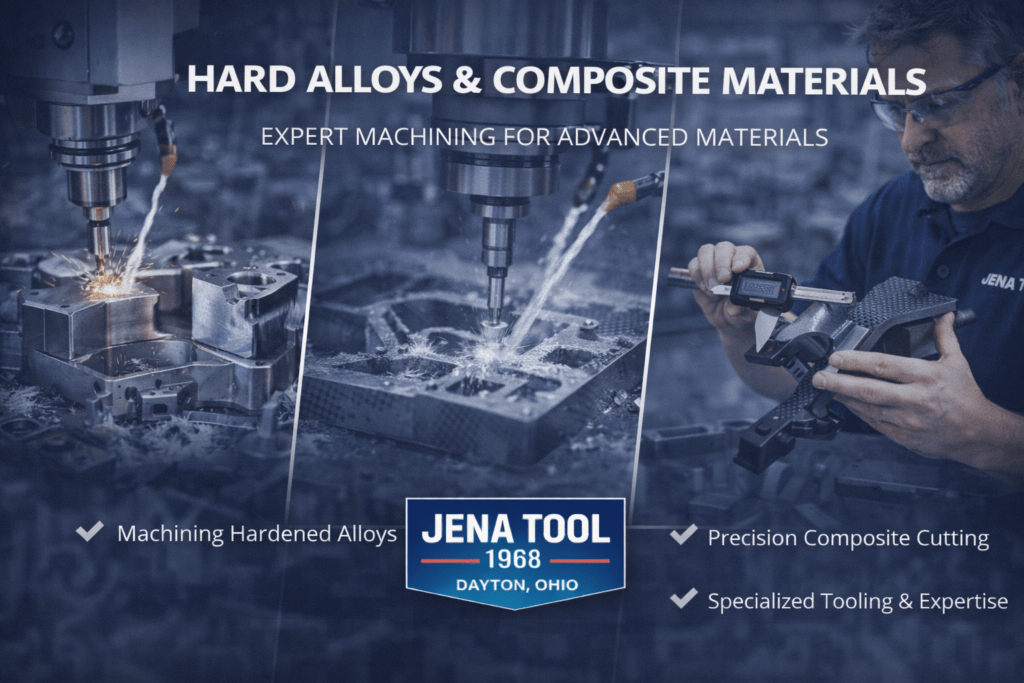

Hard Alloys & Composite Materials

Home / Our Services / Machining / Hard Alloys & Composite Materials

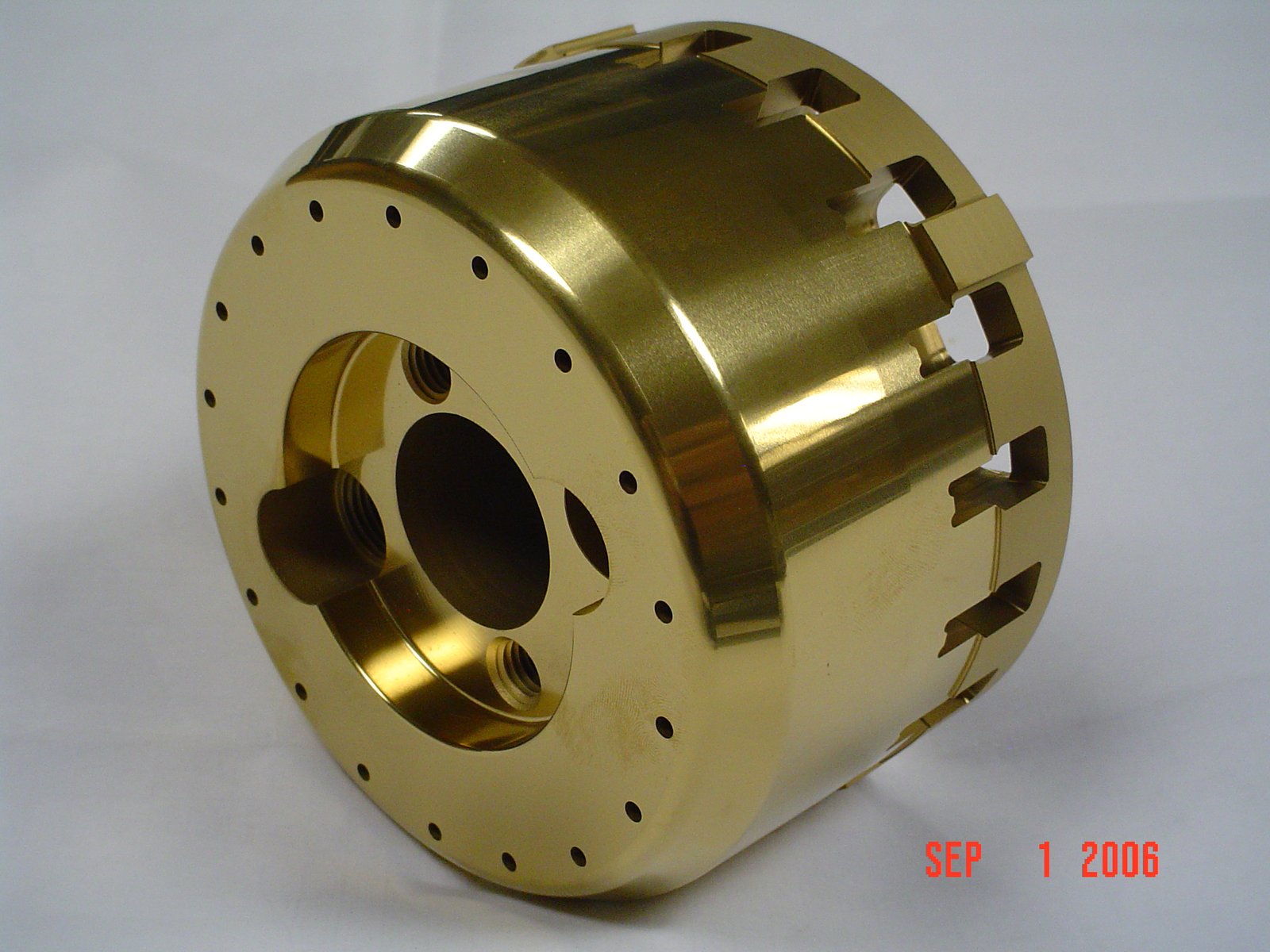

Machining Advanced Materials for High-Performance Industries

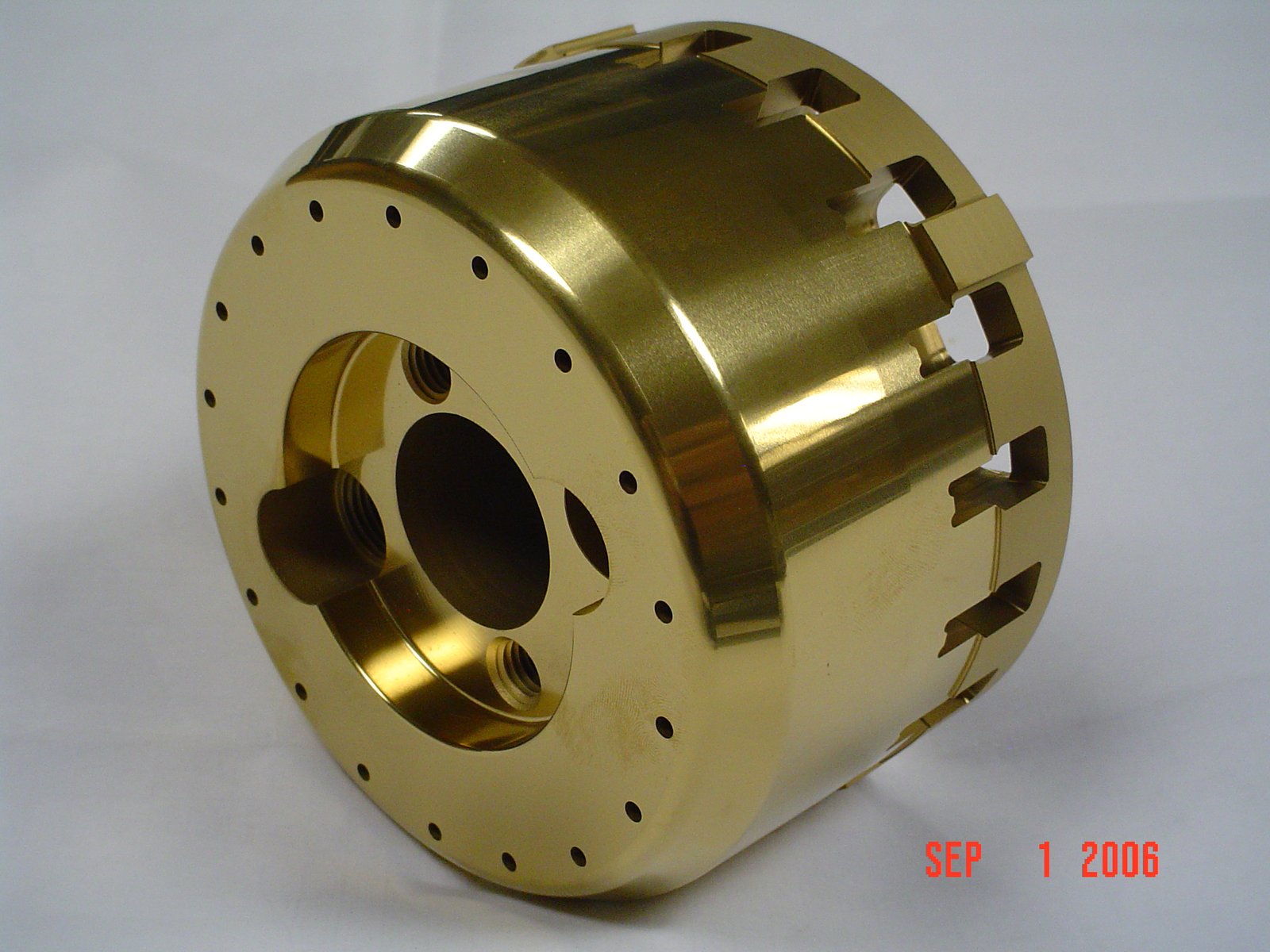

Jena Tool specializes in precision machining of hard alloys and advanced composite materials used in demanding industries such as aerospace, defense, energy, and medical manufacturing. Our expertise allows us to work with materials that require extreme accuracy, durability, and thermal resistance.

Materials We Machine

High-Temperature Alloys (Heat-Resistant Alloys)

Engineered for extreme operating environments where strength and stability are critical.

Inconel Alloys

Ideal for aerospace, turbine, and high-stress applications due to exceptional corrosion and heat resistance.

Hardened Tool Steels & Specialty Metals

Designed for long-lasting performance and precision-critical components.

Advanced Composite Materials

Including carbon fiber and engineered composites for lightweight yet high-strength solutions.

Aerospace & High-Performance Applications

Our capabilities support aerospace-grade components where tight tolerances, complex geometries, and strict quality standards are mandatory. From structural components to high-heat engine parts, we deliver precision parts that perform under pressure.

Engineering Advantages

Machining hard alloys requires experience and process control. Our team focuses on:

✔ Minimizing tool wear

✔ Controlling heat generation

✔ Maintaining tight tolerances

✔ Ensuring superior surface finishes

✔ Reducing material stress and distortion

✔ Maximizing part performance and longevity

Why It Matters

Machining hard alloys and composites requires specialized tooling, optimized cutting strategies, and deep material knowledge. Jena Tool combines advanced CNC technology, skilled craftsmanship, and process control to ensure:

Superior dimensional accuracy

Excellent surface finishes

Reduced material stress and distortion

Reliable performance in extreme environments

When precision, strength, and durability are non-negotiable, Jena Tool delivers solutions engineered for performance.

Why Choose Jena Tool for Advanced Materials?

With over five decades of precision manufacturing experience, we combine advanced technology with deep material expertise to deliver dependable, high-performance components.

When strength, precision, and reliability matter — Jena Tool delivers.

Our Advanced Capabilities

To ensure optimal results with hard alloys and composites, Jena Tool utilizes:

• Multi-Axis CNC Machining Centers

• High-Speed Precision Machining

• Electrical Discharge Machining (EDM)

• Hard Milling & Turning

• Specialized Tooling Strategies

• Thermal Control & Process Optimization

• Advanced Inspection & Quality Verification

Ready to Start Your Project?

Our engineering team is here to help you design, develop, and scale your next product with accuracy and confidence.

FAQ

Jena Tool supports aerospace, automotive, medical, precision optics, alternative energy, electronics, oil & gas (including subsea), appliance manufacturing, heavy truck, and industrial sectors requiring tight-tolerance precision machining.

- Yes. We offer complete prototype-to-production solutions, including engineering support, tooling, CNC machining, inspection, packaging, inventory management, and shipping — all under one roof.

We machine hardened tool steels, high-temperature alloys, Inconel, titanium, nickel-based superalloys, aluminum, specialty metals, and advanced composite materials used in aerospace and high-performance applications.

- Our capabilities include multi-axis CNC machining, high-speed precision machining, EDM (Electrical Discharge Machining), hard milling and turning, contract manufacturing, and complex assembly solutions.

Absolutely. Precision is our foundation. We specialize in high-accuracy components that meet strict dimensional and performance requirements.

Your Benefits

✔ Superior strength for high-stress applications

✔ Exceptional heat resistance for extreme environments

✔ Outstanding corrosion and oxidation protection

✔ Lightweight performance with maximum durability

✔ Tight-tolerance precision machining capability

✔ Extended component lifecycle and reduced maintenance

✔ Reliable performance in aerospace-grade applications

✔ Enhanced structural integrity under heavy loads

✔ Consistent dimensional accuracy in complex geometries

✔ Optimized efficiency in high-performance systems