End to End Contract Manufacturing

Home / Our Services / Manufacturing /End to End Contract Manufacturing

End-to-End Contract Manufacturing

At Jena Tool, we provide complete end-to-end contract manufacturing solutions — transforming your concept into a fully engineered, precision-manufactured product ready for market.

From early-stage design collaboration to full-scale production, assembly, inspection, packaging, and delivery — we manage the entire lifecycle under one roof.

You focus on growing your business.

We handle the manufacturing.

Specialized Product Applications We Manufacture

Jena Tool supports a wide range of complex industrial and commercial products, including:

Enclosures & Chassis – Rack Mount Systems

Modular Systems & Lighting Fixtures

Control Cabinets & Electrical Panels

Data Center Products, Racking & Enclosures

PDU (Power Distribution Units), RPP (Remote Power Panels) & Robotics Parts

Our integrated manufacturing approach ensures structural integrity, precision tolerances, electrical reliability, and scalable production for demanding industries.

Industries We Support

Aerospace & Defense

Automotive & Transportation

Energy & Alternative Energy

Medical Equipment

Industrial Equipment

Precision Optics

Electronics & Electrical Systems

Heavy Equipment & Manufacturing

Our Commitment

We don’t just manufacture parts —

we build long-term partnerships based on reliability, technical excellence, and consistent on-time delivery.

With decades of precision manufacturing expertise, Jena Tool becomes an extension of your production team — committed to performance, quality, and growth.

Why Choose Jena Tool for Contract Manufacturing?

- Single-Source Accountability

One partner. One process. Total responsibility from prototype to production. - Reduced Lead Times

Integratedcapabilities eliminate delays between vendors. - Cost Optimization

Efficient process engineering and value-driven manufacturing reduce overall production costs. - Scalable Production

From low-volume prototypes to high-volume production runs. - Precision & Quality Assurance

ISO-compliant systems with strict inspection protocols at every stage. - Confidential & Secure Operations

Your designs and intellectual property remain protected.

What We Deliver

Product Design & Engineering Support

Process Development & Optimization

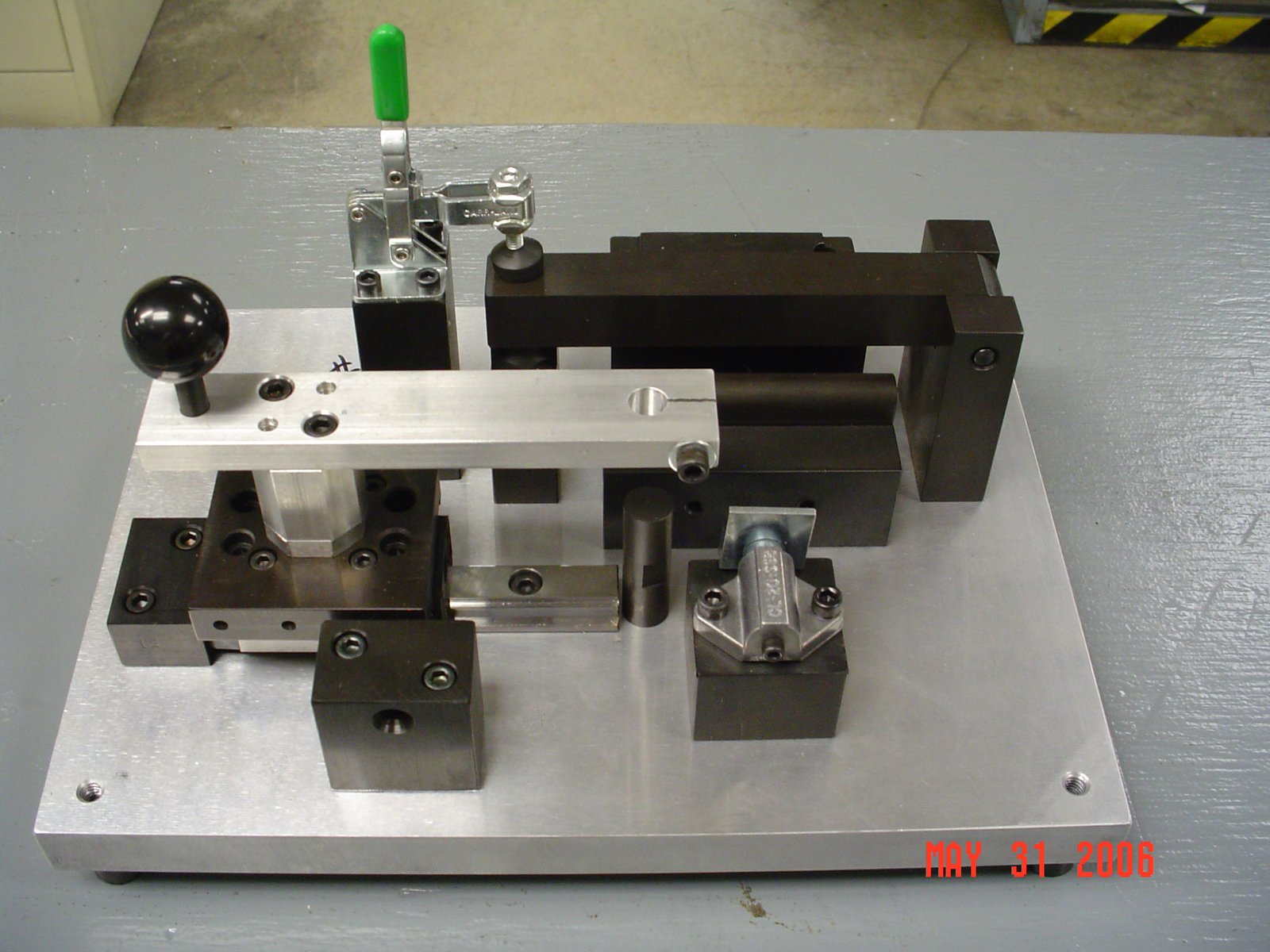

Tooling Design & Fabrication

Multi-Axis CNC Precision Machining

Sheet Metal Fabrication

Electrical Assemblies & Bus Bar Fabrication

Powder Coating & Surface Finishing

Quality Inspection & Testing

Complete Assembly & Sub-Assembly

Inventory Management & Logistics Support

Ready to Start Your Project?

Our engineering team is here to help you design, develop, and scale your next product with accuracy and confidence.

FAQ

- Yes, we manage the complete manufacturing lifecycle under one roof.

- Absolutely — from low-volume prototypes to high-volume production runs.

- Yes, we offer complete assembly, finishing, inspection, and packaging support.

- Through strict quality control systems, precision inspection, and ISO-compliant processes.

- Yes, every solution is tailored to your technical and production needs.

Benefits

Single-source manufacturing with total accountability.

Faster lead times with integrated in-house capabilities.

Reduced overall production costs through process optimization.

Consistent precision and quality assurance.

Scalable production to match your growth.

On-time delivery you can depend on.