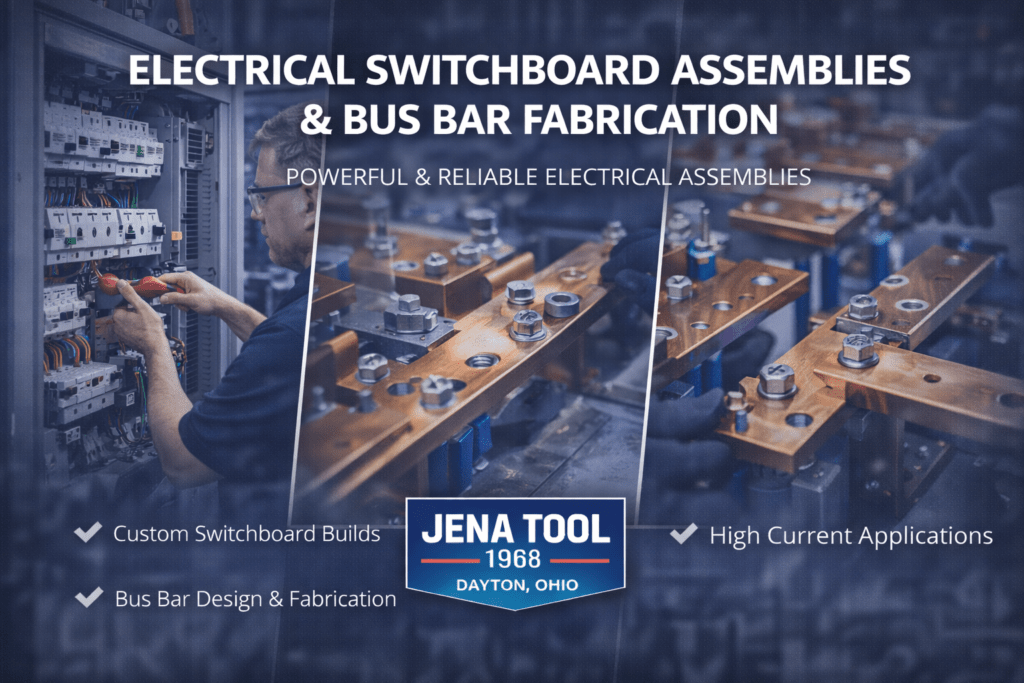

Electrical Switch board assemblies & bus bar fabrication

Home / Our Services / Manufacturing/Electrical Switch board assemblies & bus bar fabrication

High-Performance Power Distribution Solutions

At Jena Tool, we design and manufacture precision electrical switchboard assemblies and custom bus bar systems engineered for reliability, safety, and high-load performance.

Electrical switchboards and bus bars are the backbone of power distribution systems. Whether in industrial facilities, commercial buildings, energy plants, or infrastructure projects, our assemblies ensure stable, efficient, and uninterrupted power flow.

From design to fabrication and final assembly, we deliver complete, turnkey electrical metal solutions tailored to your application.

Our Capabilities

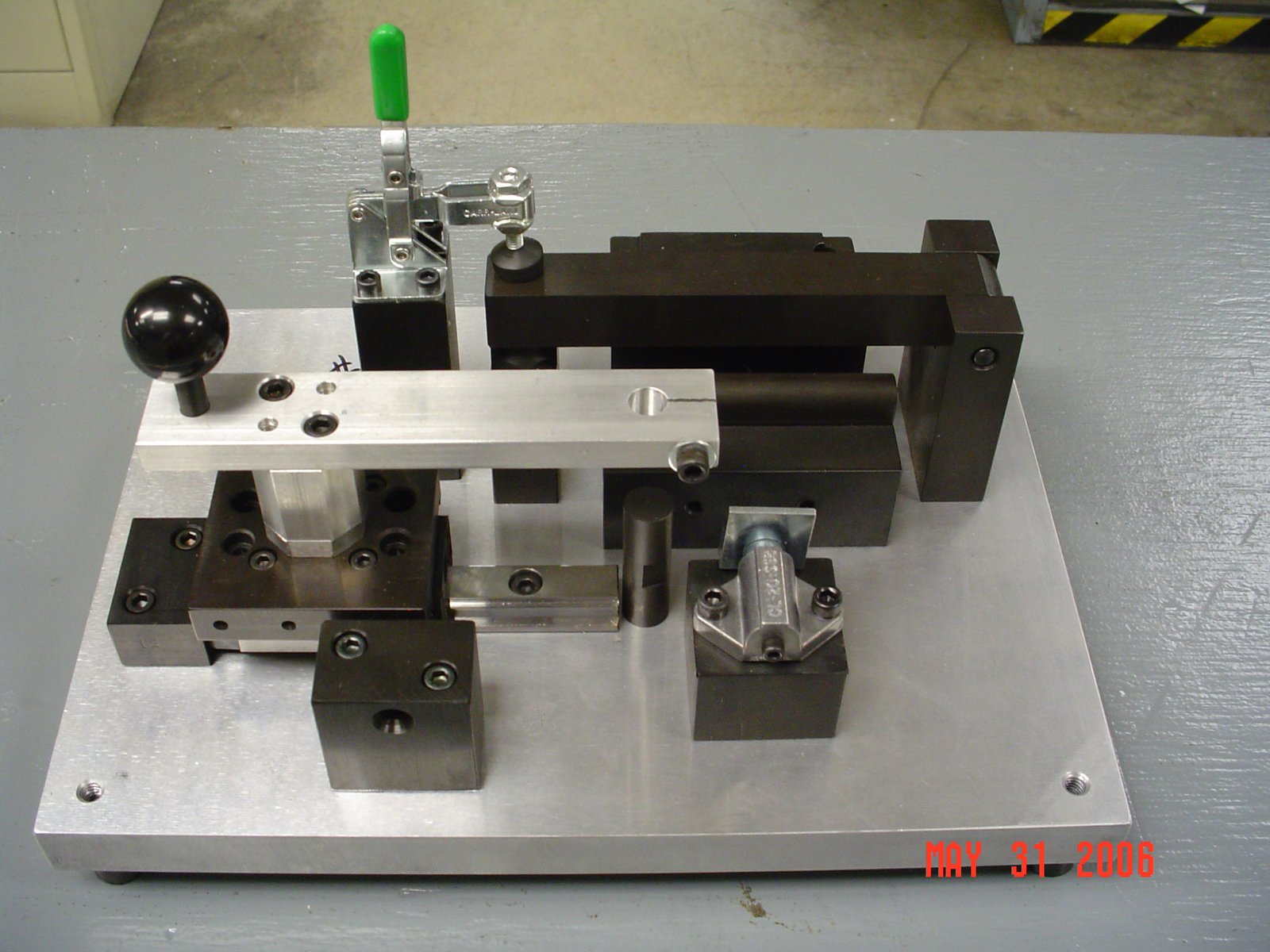

Custom Copper & Aluminum Bus Bar Fabrication

Precision Cutting, Bending & Punching

Insulated & Coated Bus Bar Systems

High-Current Distribution Assemblies

Switchboard Panel Fabrication

Powder Coating & Surface Finishing

Complete Assembly & Integration

Quality Inspection & Testing

Industries We Serve

Our electrical switchboard and bus bar systems support:

Power Generation & Energy Sector

Manufacturing & Industrial Plants

Commercial & Residential Construction

Marine & Offshore Applications

Transportation & Rail Systems

Telecommunications Infrastructure

Mining & Heavy Equipment

Engineered for Performance & Safety

Our expert fabrication team ensures:

Tight dimensional accuracy

Clean edge finishing

Proper insulation & spacing

Compliance with electrical safety standards

Long-term durability under demanding operating conditions

Every component is manufactured with strict quality control processes to ensure dependable performance in mission-critical environments.

Why Bus Bar Systems Over Conventional Cabling?

Increased Electrical Efficiency

Lower resistance and reduced energy loss compared to traditional cable systems.

Higher Current Capacity

Designed to handle heavy electrical loads safely and efficiently.

Reduced Installation Complexity

Cleaner layouts, fewer components, and simplified maintenance.

Improved Thermal Management

Optimized heat dissipation for enhanced safety and performance.

Lower Long-Term Costs

Reduced material usage, minimal wiring errors, and lower maintenance expenses.

Enhanced Reliability

Minimizes connection failures and improves system stability.

Complete Turnkey Support

We don’t just fabricate — we integrate.

From raw material processing to final assembly and finishing, Jena Tool provides a streamlined manufacturing process that saves time, reduces vendor complexity, and ensures consistent quality.

If you’re looking for reliable, precision-engineered electrical switchboard assemblies and bus bar fabrication, we’re ready to deliver.

Ready to Start Your Project?

Our engineering team is here to help you design, develop, and scale your next product with accuracy and confidence.

FAQ

- We manufacture custom bus bars using high-grade copper and aluminum for maximum conductivity and durability.

- Yes, we deliver complete switchboard assemblies ready for integration and installation.

- Absolutely, our systems are engineered for heavy-load, high-performance power distribution.

- Yes, all assemblies are tailored to meet specific electrical and dimensional requirements.

Every unit undergoes strict inspection and quality checks to ensure safety and reliability.

Benefits

High electrical efficiency with reduced power loss.

Superior current-carrying capacity.

Compact, space-saving installation design.

Improved thermal performance and safety.

Reduced maintenance and long-term costs.

Engineered for durability in demanding environments.

Complete turnkey manufacturing under one roof.