Electrical Discharge Machining (EDM)

Home / Our Services / Machining / Electrical Discharge Machining

High-Precision Machining for Complex & Hard Materials

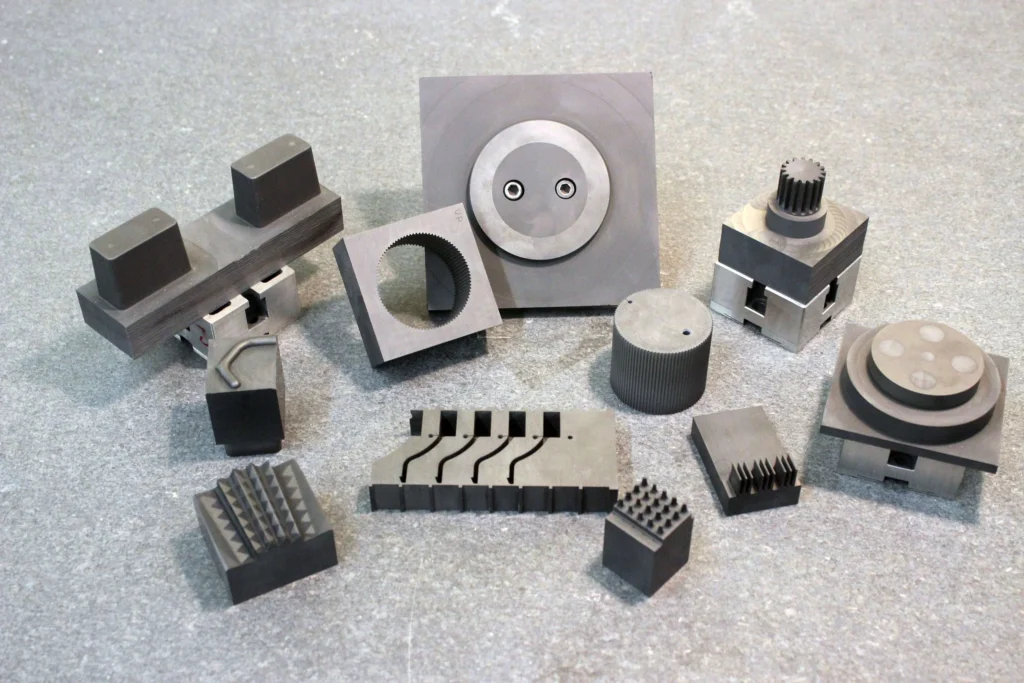

Electrical Discharge Machining (EDM) is an advanced manufacturing process used to cut, shape, and machine electrically conductive materials with extreme precision. Using controlled electrical sparks, EDM removes material without any physical contact — making it ideal for complex geometries, hardened metals, and ultra-fine tolerances.

What is EDM?

EDM is a thermal process in which sparks are generated between an electrode and the workpiece. These sparks create tiny craters that gradually shape the material into the desired form. It is widely used where traditional machining tools cannot reach or cannot achieve the required accuracy.

Our EDM Capabilities

- Used for cutting detailed shapes with outstanding accuracy.

Perfect for dies, molds, precision components, and complex profiles.

- Creates deep cavities, intricate pockets, and precise mold features.

Best choice for mold tooling, punches, and hardened parts.

For ultra-small features, micro-holes, and miniature components.

Used in medical, electronics, aerospace, and precision tooling.

Why EDM Is Used

Can machine very hard materials like tool steel, carbide, titanium, Inconel, etc.

Ideal for complex shapes, fine cavities, sharp corners, and intricate contours.

No mechanical force → perfect for delicate or thin components.

Achieves micron-level accuracy and mirror-like finish.

How Our System Works

Clear, Efficient & Quality-Driven Workflow

We begin by understanding your specific needs — product drawings, tolerances, materials, and application requirements. This helps us design a solution that fits perfectly into your process.

Our design engineers create detailed 3D models using advanced CAD/CAM software. Every dimension, angle, and feature is carefully planned to ensure accuracy, durability, and manufacturability.

Before manufacturing starts, the design is tested through simulations to predict performance, stress points, and machining behavior. This reduces errors and ensures the design is production-ready.

- Using CNC machining, EDM, and other advanced processes, we convert the design into high-precision components. Every part is produced with strict tolerance control and premium-quality materials.

Each component undergoes thorough inspection — dimensional checks, tolerance verification, hardness testing, and finish analysis — ensuring the final output meets the required standards.

For tooling and assemblies, we perform trial fits and operational tests to confirm flawless performance before dispatch.

We deliver the project on time with complete documentation and provide ongoing technical support for installation, integration, and maintenance.

Ready to Start Your Project?

Our engineering team is here to help you design, develop, and scale your next product with accuracy and confidence.

FAQ

EDM is a high-precision machining process that uses electrical sparks to cut and shape conductive materials without physical contact, making it ideal for complex and hardened components.

We can machine all electrically conductive materials, including hardened steel, tool steel, carbide, titanium, copper, brass, and exotic alloys like Inconel.

We offer Wire EDM, Die-Sinking EDM, and Micro EDM to handle everything from intricate profiles to deep cavities and miniature components.

- EDM can achieve extremely tight tolerances, typically within ±2–5 microns, depending on the part complexity.

Yes. EDM is specifically used for machining hardened metals that traditional machining cannot cut efficiently.

Your Benefits

- High Precision & Accuracy

Achieve tight tolerances, complex geometries, and superior surface finishes with our advanced machining and engineering processes.

- Reduced Manufacturing Costs

Optimized designs, efficient processes, and minimal rework lower the overall cost of production significantly.

- Faster Production & Shorter Lead Times

Streamlined workflows, advanced CAD/CAM systems, and high-speed machining ensure quick turnaround without compromising quality.

- Enhanced Tool Life & Durability

Premium materials and refined manufacturing techniques increase tool longevity and reduce downtime.

- Improved Product Quality & Consistency

Every part undergoes strict quality checks, ensuring accuracy, reliability, and consistent performance across batches.