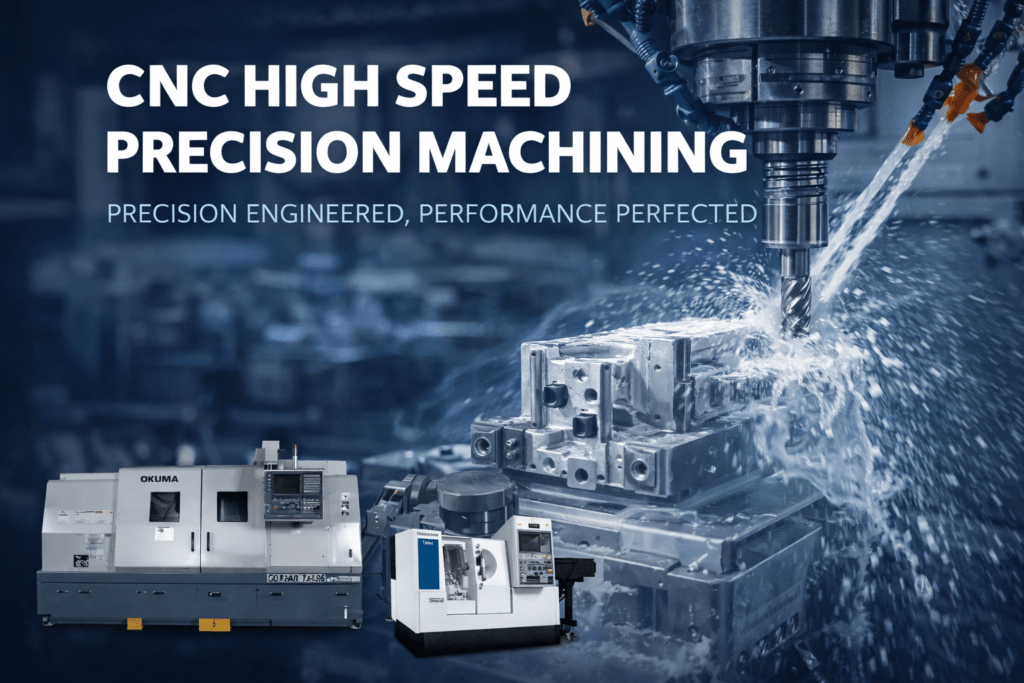

CNC High Speed Precision Machining

Home / Our Services / Machining / CNC High Speed Precision Machining

Precision. Speed. Complex Geometry — Delivered with Accuracy.

At Jena Tool, our CNC High Speed Precision Machining combines advanced multi-axis capabilities with high-speed production technology to deliver superior accuracy, tighter tolerances, and faster turnaround times.

We specialize in machining complex components that demand precision, repeatability, and performance in the most demanding industries.

What is CNC High Speed Precision Machining?

CNC High Speed Precision Machining integrates:

• Multi-Axis CNC Machining (3-Axis, 4-Axis, and 5-Axis)

• High-Speed Milling & Cutting Strategies

• Advanced CAD/CAM Programming

• Tight Tolerance Production

• Precision Inspection & Quality Control

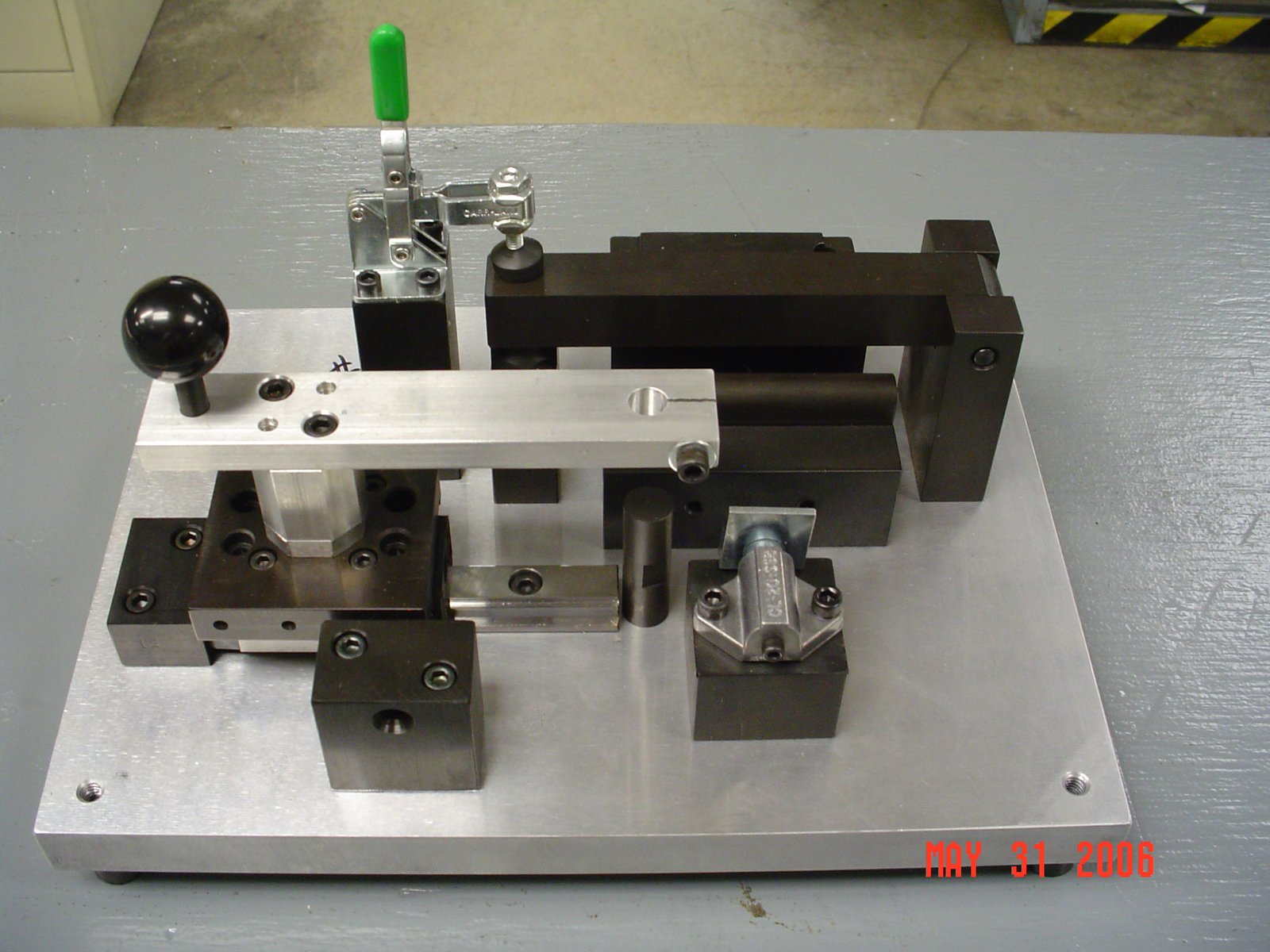

This combination allows us to machine complex geometries, curved surfaces, deep cavities, intricate contours, and high-performance components — all in fewer setups and with greater accuracy.

Our Capabilities

Multi-Axis CNC Machining

• 3-Axis CNC Machining

• 4-Axis CNC Machining

• 5-Axis CNC Machining

• Simultaneous Multi-Axis Cutting

High Speed Precision Machining

• Reduced Cycle Times

• Superior Surface Finish

• Tight Tolerance Machining

• Hard Material Machining

• Prototype to Production

Engineering & Programming

• CAD/CAM Programming

• 3D Modeling & Simulation

• Tool Path Optimization

• Process Validation

Industries We Serve

Our CNC High Speed Precision Machining supports:

• Aerospace

• Automotive

• Medical

• Energy

• Heavy Equipment

• Industrial Manufacturing

• Precision Optics

When tolerances are tight and performance cannot fail — our machining delivers.

How Our System Works

- Requirement Understanding & Consultation

- Engineering Design & 3D Modeling

- Simulation & Process Validation

- CNC Programming & Setup

- High Speed Precision Machining

- Quality Inspection & Testing

- Final Delivery & Ongoing Support

Our streamlined workflow ensures complete transparency, reduced production errors, and optimized efficiency from concept to completion.

Why Choose CNC High Speed Precision Machining?

- Maximum Accuracy & Consistency

Advanced multi-axis control ensures repeatable precision in every production run.

- Faster Production with Lower Costs

High-speed machining reduces cycle time, improving output and lowering overall manufacturing cost. - Superior Surface Finish

Smooth finishes minimize post-processing requirements and improve final part performance. - Reduced Setup & Tool Wear

Fewer setups mean improved dimensional accuracy and increased tool life. - Ideal for Complex & Critical Parts

Perfect for intricate geometries, deep cavities, undercuts, multi-surface components, and performance-driven parts.

Why Jena Tool?

• Over 50 Years of Proven Experience

• Advanced CNC & Multi-Axis Technology

• Complete Turnkey Manufacturing

• Precision Inspection & Quality Assurance

• On-Time Delivery & Production Reliability

Ready to Start Your Project?

Our engineering team is here to help you design, develop, and scale your next product with accuracy and confidence.

FAQ

- We machine aluminum, steel, stainless steel, titanium, brass, copper, tool steel, hardened materials, and specialty alloys.

- Yes. Our 4-Axis and 5-Axis CNC capabilities allow us to machine curved surfaces, intricate geometries, and deep cavities efficiently.

- Yes. We support rapid prototyping through full-scale production runs.

- We achieve tight tolerances depending on material and part complexity.

Absolutely. We accept standard CAD formats and optimize them for production.

CNC High Speed Precision Machining – Benefits

• High precision with tight tolerance accuracy

• Faster production with reduced cycle time

• Superior surface finish and part quality

• Fewer setups for improved dimensional consistency

• Lower overall manufacturing cost

• Capability to machine complex geometries

• Reduced tool wear and longer tool life

• Consistent repeatability in every batch

• Ideal for critical and high-performance components

• Scalable from prototype to full production